What chemicals are contained in the bowls that hold your fast food order? This question delves into the often-overlooked world of food packaging materials, exploring the potential impact of these seemingly innocuous containers on our health and the environment. We’ll examine the materials used, the potential for chemical migration, regulations, environmental concerns, and even alternative solutions.

From the ubiquitous Styrofoam to increasingly common paper and plastic options, the chemical composition of these bowls varies significantly. Understanding these differences is crucial to making informed choices about the food we consume.

Identifying Materials

Fast food containers are ubiquitous, but how much do we really know about the materials they’re made from? From the satisfying crunch of a paper bowl to the sometimes-slippery surface of a plastic one, the materials used play a critical role in our experience and the environmental impact of our consumption habits. This section delves into the composition and properties of common fast food bowl materials, illuminating the chemistry behind the convenience.The choice of material for fast food containers is driven by several factors, including cost-effectiveness, durability, ease of use in production, and, increasingly, environmental concerns.

Understanding the chemical makeup of these materials helps us assess their potential impact on our health and the environment.

Common Fast Food Bowl Materials

The materials used for fast food bowls are diverse, each with its own characteristics. This section presents a breakdown of common materials, examining their chemical compositions and durability.

- Styrofoam (Expanded Polystyrene): Styrofoam is a ubiquitous choice for fast food containers due to its lightweight nature and insulation properties. It’s primarily composed of polystyrene, a synthetic polymer. The polystyrene chains are expanded with air, leading to a porous structure. This results in a lightweight, inexpensive, and surprisingly durable material, capable of holding hot or cold foods. However, its longevity is limited by factors like degradation from exposure to UV radiation and potential leaching of chemicals under extreme temperatures.

Its durability is dependent on the type of styrofoam, as different grades offer different levels of heat and chemical resistance.

- Paper: Paper bowls, often coated with a thin layer of wax or other materials for protection and water resistance, are commonly used for takeout. Paper’s primary component is cellulose, a natural polymer derived from wood pulp. The chemical composition can vary based on the manufacturing process and additives used to improve its properties, such as wax or other coatings for added durability and water resistance.

Paper’s durability is dependent on the thickness and coatings applied; it’s generally less durable than styrofoam and more susceptible to tearing or moisture absorption. The lifespan of paper bowls is often shorter than those of plastic, depending on use conditions.

- Plastic (Various Types): Plastic bowls, often made from polyethylene (PE) or polypropylene (PP), are frequently used for their versatility. Polyethylene is a thermoplastic polymer composed of long chains of ethylene molecules. Polypropylene is another thermoplastic polymer, composed of propylene molecules. Plastic’s durability is significantly higher than paper and often comparable to styrofoam, depending on the grade of plastic used and the conditions of use.

The longevity of plastic depends on the type of plastic and environmental factors. Plastic containers are more resistant to moisture and temperature changes, leading to a longer lifespan compared to paper, though certain types of plastic may degrade over time or leach chemicals.

Chemical Composition and Durability Comparison

This table summarizes the chemical composition and durability of the materials discussed.

| Material Type | Chemical Composition | Durability |

|---|---|---|

| Styrofoam (Expanded Polystyrene) | Polystyrene chains expanded with air | Good for short-term use, can degrade with UV exposure or extreme temperatures. |

| Paper | Cellulose, often with wax or other coatings | Lower than styrofoam and plastic, prone to tearing and moisture absorption. |

| Plastic (Polyethylene/Polypropylene) | Polyethylene (PE) or Polypropylene (PP) polymers | High durability, more resistant to moisture and temperature changes compared to paper, dependent on the grade of plastic. |

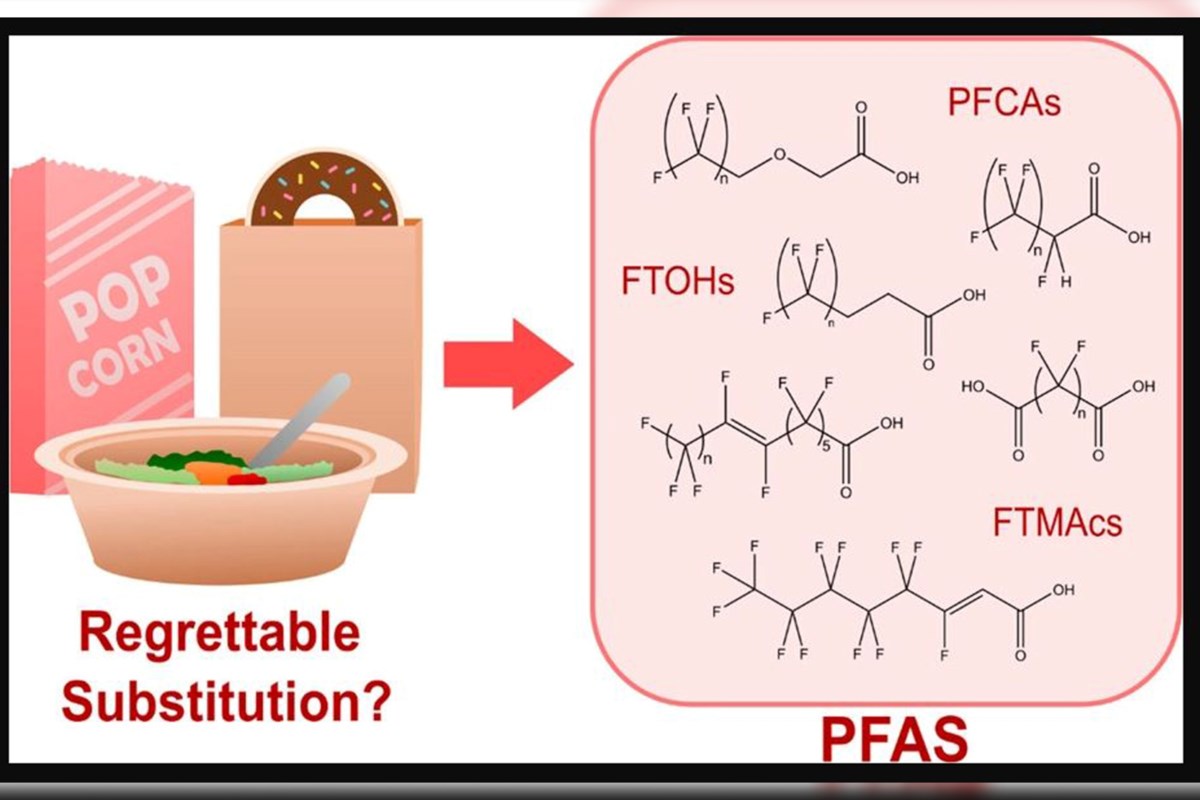

Migration of Chemicals

Fast food containers, often made from various plastics and coatings, can potentially release chemicals into the food they hold. Understanding the factors influencing this migration is crucial for assessing the potential health implications of consuming food served in these containers. This process, known as leaching, is a complex interplay of different environmental conditions and material properties.

Factors Influencing Chemical Migration

The journey of chemicals from the container to the food is affected by a variety of factors. Temperature plays a significant role, as higher temperatures generally accelerate the leaching process. Acidity and alkalinity of the food also influence the rate of chemical migration. The length of time the food remains in contact with the container is another critical factor.

The specific chemical composition of both the food and the container also plays a pivotal role.

Examples of Potentially Migrating Chemicals and Their Potential Health Effects

Some chemicals commonly found in food containers, such as Bisphenol A (BPA), phthalates, and certain plasticizers, can potentially migrate into food. BPA, for instance, has been linked to hormonal disruption in some studies, although the exact health effects remain a subject of ongoing research and debate. Phthalates are known to disrupt hormone function, and their presence in food raises concerns about potential long-term health consequences.

It’s crucial to note that the concentration of these chemicals migrating into food often remains relatively low, and the health implications are not always straightforward. The long-term effects of exposure to these chemicals at low concentrations remain a subject of ongoing research and public health scrutiny.

Table: Factors Affecting Chemical Migration

| Factor | Explanation | Potential Impact |

|---|---|---|

| Temperature | Higher temperatures increase the rate of chemical migration. | Increased risk of chemical leaching into food, potentially affecting the health of consumers. |

| Acidity/Alkalinity of Food | Acidic or alkaline foods can alter the chemical structure of the container material, increasing migration. | Potentially increased release of chemicals into food. |

| Contact Time | The longer food remains in contact with the container, the greater the potential for chemical migration. | Higher risk of exposure to chemicals, depending on the rate of migration. |

| Chemical Composition of Food | Certain components in food can interact with container materials, accelerating leaching. | Potential for altered chemical content in food, depending on specific interactions. |

| Chemical Composition of Container | The type and concentration of chemicals in the container material affect migration rates. | Different materials have different chemical profiles, leading to variable migration rates. |

Regulations and Standards

Navigating the world of food contact materials requires a deep understanding of the regulations and standards governing their use. These guidelines ensure the safety of consumers by establishing limits on the migration of potentially harmful chemicals from packaging into food. Compliance with these regulations is crucial for maintaining public trust and upholding food safety standards.Food contact materials, like the bowls and containers used in fast food, are subject to stringent regulations to protect consumer health.

These regulations are not static; they evolve to reflect the latest scientific understanding of material safety and potential hazards. Different regions have their own sets of regulations, reflecting varying priorities and approaches to food safety.

Relevant Regulations Regarding Food Contact Materials

Regulations governing food contact materials are designed to prevent the transfer of harmful substances from the packaging into the food. These regulations often cover the materials used, their processing, and the testing procedures employed to ensure safety.

- The US Food and Drug Administration (FDA) has a comprehensive set of regulations concerning food contact substances. These regulations specify the acceptable levels of certain chemicals that can migrate from materials into food. The FDA regulates the safety of additives and food contact substances, ensuring they don’t pose a risk to consumers.

- The European Union (EU) has stringent regulations regarding food contact materials, encompassing a wide range of materials and applications. These regulations establish limits on the migration of substances into food and require manufacturers to demonstrate the safety of their products. The EU’s approach is known for its comprehensive and detailed nature, often requiring extensive testing.

- Other countries like Japan, China, and Australia also have their own regulations. These regulations vary based on the specific needs and priorities of each country. Their standards often reflect the scientific knowledge and priorities of the region.

Testing Procedures for Food Contact Materials

The safety of food contact materials is determined through rigorous testing procedures. These tests assess the potential for harmful chemicals to migrate into food under various conditions, simulating real-world scenarios.

- Migration tests are crucial for evaluating the potential for chemicals to leach into food. These tests often involve exposing the material to food simulants at specific temperatures and durations to simulate real-world conditions. The results are then compared to established safety limits.

- The specific testing procedures often vary based on the material and the intended food application. For example, the testing protocols for plastics differ from those for metals. Factors such as the type of food, temperature, and duration of contact all influence the procedures.

- The tests must be conducted by accredited laboratories that follow standardized protocols. This ensures the reliability and validity of the results. Such laboratories are equipped with specialized equipment and trained personnel to perform the tests accurately.

Standards and Certifications for Food-Safe Materials

Several standards and certifications are available to demonstrate the safety and quality of food contact materials. These certifications act as assurance mechanisms for consumers and businesses.

- Certifications like the NSF International certification for food contact materials indicate compliance with stringent safety standards. This certification provides assurance that the materials meet established requirements for food safety.

- Many organizations provide standards and certifications for food-safe materials, ensuring that manufacturers adhere to quality and safety protocols. These organizations often conduct rigorous evaluations to ensure compliance with established safety guidelines.

- The presence of such certifications signifies that the material has undergone rigorous testing and is deemed safe for contact with food. These certifications provide a level of confidence for consumers and businesses alike.

Comparison of Regulations in Different Countries

| Country | Regulations | Testing Procedures |

|---|---|---|

| United States (FDA) | Specifies acceptable levels of chemical migration into food. Focuses on additives and food contact substances. | Migration tests using food simulants at specified temperatures and durations. |

| European Union (EU) | Comprehensive regulations covering a wide range of materials and applications. Limits migration of substances into food. | Detailed migration tests, often requiring extensive evaluations. |

| Japan | Specific regulations for food contact materials, reflecting the country’s specific needs and priorities. | Testing procedures based on Japanese standards and guidelines. |

| China | Regulations evolve with scientific understanding of material safety and potential hazards. | Testing procedures are aligned with national food safety standards. |

Environmental Impact: What Chemicals Are Contained In The Bowls That Hold Your Fast Food Order

Fast food containers, though convenient, contribute significantly to environmental concerns throughout their lifecycle. From the raw materials extraction to the final disposal, each stage presents potential impacts on ecosystems and human health. Understanding these impacts is crucial for making informed decisions about sustainable practices in the food service industry.The manufacturing process for these containers often involves the use of fossil fuels and energy-intensive production methods.

Ever wondered what’s lurking in those disposable fast food bowls? Turns out, they’re often coated with a variety of chemicals, and let’s be honest, your kitchen towels are probably full of bacteria too. This article highlights just how germy those seemingly clean towels can be, which makes you think twice about the hidden nasties in your food packaging.

So, next time you’re grabbing a quick bite, remember those bowls are likely harboring more than just your meal.

Disposal presents a further challenge, as many materials are not easily recycled or biodegrade, leading to persistent waste in landfills. These environmental considerations necessitate a holistic evaluation of the entire fast food bowl lifecycle.

Manufacturing Impacts

The production of fast food bowls, like other consumer products, necessitates significant energy consumption and resource depletion. The extraction of raw materials, often involving mining or deforestation, has detrimental effects on biodiversity and ecosystems. Energy-intensive processes, such as molding and processing, release greenhouse gases and contribute to air pollution. The selection of materials for bowl production plays a vital role in determining the overall environmental footprint.

Disposal and Waste Management

The disposal of fast food bowls often leads to environmental problems. If not properly managed, these bowls end up in landfills, where they can take centuries to decompose. This accumulation of non-biodegradable waste contributes to landfill expansion and pollution. Landfill leachate, containing chemicals potentially migrating from the bowls, can contaminate groundwater and soil.

Recyclability of Materials

The recyclability of fast food bowls varies significantly based on the materials used in their construction. Some materials, like paper or cardboard, are more easily recycled than others, such as plastic or styrofoam. The efficient recycling of these materials depends on effective sorting and processing infrastructure. The availability and efficiency of recycling programs also influence the overall environmental impact of fast food bowls.

Chemical Runoff Potential

The potential for chemical runoff from fast food bowls into the environment is a concern, particularly if the bowls contain materials that leach chemicals under certain conditions. The presence of additives, such as plasticizers or pigments, may lead to chemical contamination of water sources or soil. Studies on the long-term effects of chemical leaching from these materials are crucial to assess the environmental risks.

Lifecycle Assessment of a Fast-Food Bowl

A comprehensive lifecycle assessment of a fast food bowl encompasses the entire production process, from raw material extraction to final disposal. The extraction of raw materials (e.g., minerals for plastic production, trees for paper) often involves deforestation or habitat disruption. Manufacturing processes, including molding and processing, contribute to greenhouse gas emissions and air pollution. The use of the bowl for food service has little direct environmental impact.

Ultimately, the disposal stage presents significant challenges, depending on the recyclability of the material and the effectiveness of waste management practices.

Alternatives and Innovations

The quest for sustainable packaging solutions extends beyond simply identifying and understanding the chemicals in existing fast food containers. Finding viable alternatives is crucial for reducing the environmental footprint of the food service industry. This section delves into innovative materials, their chemical properties, and their potential to revolutionize the way we package our food.Moving away from traditional petroleum-based plastics opens a world of possibilities, but each alternative comes with its own set of advantages and disadvantages.

Careful consideration of these trade-offs is essential to identifying the most effective and environmentally responsible solutions.

Biodegradable Plastics

Biodegradable plastics, derived from renewable resources like cornstarch or sugarcane, offer a promising pathway towards sustainability. These materials break down naturally over time, reducing the long-term impact on landfills.

Ever wondered what’s lurking in those styrofoam bowls holding your fast food? Turns out, there are a whole host of chemicals, some potentially harmful. It’s a stark contrast to the happy news of Ann Hathaway’s pregnancy after fertility struggles, a truly inspiring story. Ann Hathaway reveals pregnancy after fertility struggles. Still, those bowls aren’t exactly a health food haven, are they?

Knowing what’s in them is crucial for making informed choices about what we eat.

- Chemical Properties: Biodegradable plastics often contain additives that influence their degradation rate and strength. The specific chemical composition varies depending on the source material and intended application.

- Advantages: These materials offer a potential reduction in reliance on fossil fuels and contribute to a more circular economy. Their natural degradation can decrease landfill burden.

- Disadvantages: Biodegradability can be influenced by factors like temperature and moisture content. The degradation process might not be as rapid as desired in certain environments, and the overall performance characteristics of some biodegradable plastics might not match those of traditional plastics.

Plant-Based Materials, What chemicals are contained in the bowls that hold your fast food order

Plant-based materials, like paper, bamboo, and mushroom-derived plastics, offer an entirely different approach to packaging. These materials are often considered more sustainable and environmentally friendly.

Ever wondered about the chemicals lurking in those disposable fast-food bowls? It’s a fascinating topic, and thankfully, there are some fantastic apps out there to help us stay informed. For example, checking out top iPhone and Android apps like top iphone android apps can help you discover resources about hidden ingredients in everyday products, including food packaging.

Knowing more about these chemicals can empower us to make more informed choices, even when grabbing a quick bite.

- Chemical Properties: These materials vary significantly in their chemical composition. Paper, for example, is primarily cellulose, while bamboo contains lignin and cellulose. Mushroom-derived plastics utilize a complex network of polymers.

- Advantages: Plant-based materials are generally renewable, and often readily compostable. Their inherent biodegradability minimizes the long-term impact on the environment.

- Disadvantages: Some plant-based materials can be less durable than traditional plastics, potentially impacting the integrity of the food product during transportation and storage. The manufacturing process of some plant-based alternatives can be complex and energy-intensive.

Environmental Impact Comparison

A comparative analysis of the environmental impact of various materials is crucial. The table below highlights the environmental impact and cost considerations of different alternatives to traditional materials.

| Material | Environmental Impact | Cost |

|---|---|---|

| Traditional Plastic | High (long-term pollution, reliance on fossil fuels) | Low |

| Biodegradable Plastic | Medium (depends on specific composition and degradation rate) | Medium to High |

| Paper | Medium (can be recycled, but resource intensive to produce) | Low |

| Bamboo | Low (renewable resource, readily compostable) | Medium |

| Mushroom-Derived Plastic | Low (potential for significant reduction in plastic waste) | High |

Note: Environmental impact is a complex metric, and specific values depend on the specific material, manufacturing process, and disposal method. Cost varies based on the market conditions, and volume of production.

Consumer Awareness

Fast food packaging is ubiquitous, but its impact on our health and the environment deserves careful consideration. Understanding the materials used in these disposable containers, and the potential risks associated with them, empowers consumers to make more informed choices. This awareness isn’t just about individual actions; it’s a crucial step towards demanding more sustainable and safer packaging practices from corporations.Consumers can play a vital role in driving positive change by becoming informed about the materials in their food packaging.

Knowledge is power, and when armed with information, consumers can advocate for better choices, ultimately influencing the industry. This proactive approach can push manufacturers to prioritize safer and more sustainable packaging options.

Importance of Material Awareness

Knowing the composition of food packaging materials is critical for both individual well-being and broader environmental concerns. The materials used can directly impact human health through chemical migration or leaching, and contribute to the growing problem of plastic waste. This understanding allows for conscious decision-making and empowers consumers to demand better options.

Making Informed Choices

Consumers can make informed choices by seeking out information about packaging materials. Reading labels carefully, looking for certifications or standards, and researching the specific materials used are all valuable steps. Websites, environmental organizations, and even governmental agencies often provide resources for this purpose. This allows consumers to understand the potential risks and benefits associated with different materials.

Identifying Potentially Hazardous Materials

A key aspect of consumer awareness involves recognizing potential hazards in food packaging. Common materials like plastics (e.g., polystyrene, various types of polyethylene) and certain coatings can release chemicals that might be harmful if ingested or if they leach into the food.

- Look for packaging made from recycled materials, as these often have a lower environmental impact. However, be aware that not all recycled materials are created equal. Some recycled materials may still contain potentially harmful chemicals.

- Avoid packaging with unusual or unfamiliar materials. If a label contains a chemical name you can’t readily identify, you may want to consider alternatives.

- Be wary of packaging with visible imperfections or damage, as these could lead to increased chemical leaching.

- Consider purchasing food items in packaging made from materials known to be less prone to chemical leaching, such as glass or stainless steel.

Advocating for Safer Packaging

Consumers can advocate for safer packaging choices through various avenues. Supporting companies with sustainable packaging practices and demanding transparency from manufacturers are key steps. Contacting businesses and regulatory bodies to express concerns and propose solutions is also important. This engagement fosters a collective effort toward creating more responsible packaging systems.

- Supporting companies with robust sustainability policies and ethical sourcing can motivate them to prioritize safer packaging. Consumers can also encourage businesses to be transparent about the materials used in their packaging.

- Contacting local and national regulatory bodies about concerns regarding food packaging materials can help push for stricter regulations.

- Participating in or supporting advocacy groups dedicated to safer food packaging can amplify your voice and help push for systematic change.

- Encourage your local communities to demand more sustainable food packaging options.

Conclusive Thoughts

In conclusion, the hidden chemicals in fast-food bowls raise important questions about our food choices and the environmental footprint of our consumption habits. While current regulations aim to ensure safety, continued research and consumer awareness are essential to fostering a more sustainable and healthy food system. The future of packaging design, hopefully, will prioritize materials that are both safe and environmentally responsible.